PICV

Achieve perfect balance and efficiency in your HVAC system with our advanced PICV (Pressure Independent Control Valves).

The Role of Valves and Actuators in Building Efficiency

Valves and actuators, though often hidden, play a crucial role in system performance, occupant comfort, and energy efficiency. Hydronic systems, which use water to transfer heat, must remain balanced to prevent overheating, overcooling, and energy waste.

Traditionally, constant volume systems with 3- or 4-port control valves and low-speed pumps were used, but they consumed energy even when there was no demand. With the shift toward energy-efficient design, variable volume systems have become more common, delivering heat only when needed.

However, these systems can be complex, requiring differential pressure control valves, 2-port control valves, and balancing valves to maintain equilibrium.

Advantages and Selection of Pressure Independent Control Valves (PICVs)

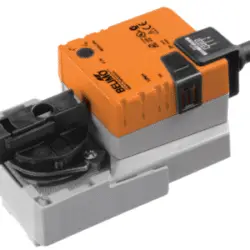

Pressure Independent Control Valves (PICVs) simplify the design and management of variable volume systems by combining three functions—control, balancing, and pressure regulation—into a single device.

They make installation and commissioning easier while improving efficiency and performance. When selecting a PICV, factors such as flow control accuracy, flow rate, manual setting capability, and actuator compatibility should be considered.

Modern PICVs often feature quick-fit actuator connections and offer a wide range of flow rates, enabling smaller valve sizes that still meet system requirements. However, engineers must also account for pressure variations—smaller valves typically require around 15kPa, while larger ones may need up to 30kPa—which can impact system operating costs.

Important Factor

Selecting the right PICV is equally important, as not all valves offer the same performance. Reliable manufacturers, such as those testing to BTS01 and BSRIA standards, ensure consistent pressure and flow control. With correct pairing, installation, and testing, PICVs provide a durable and cost-effective foundation for efficient heating and cooling systems in modern buildings.