Ultrasonic Flow / Heat Meter

£1,069.00 Original price was: £1,069.00.£806.00Current price is: £806.00.

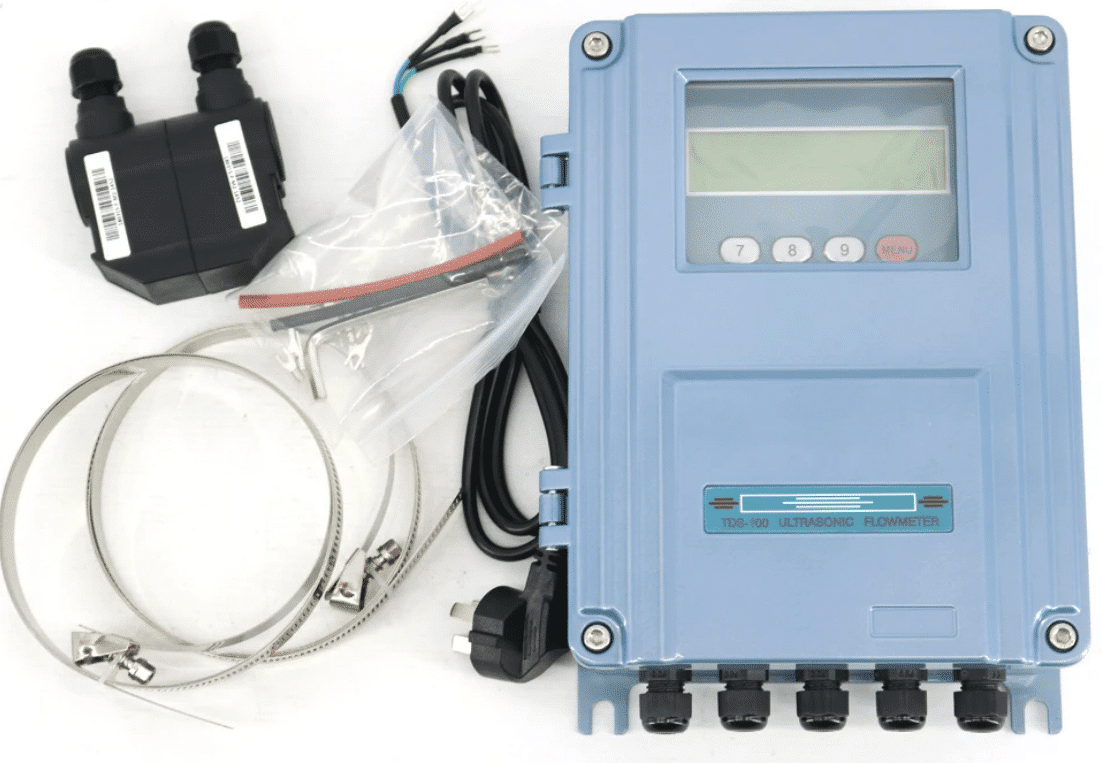

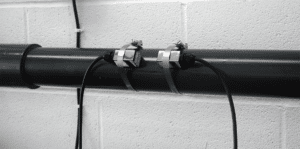

BFU-100-F Fixed Ultrasonic Flow Meter Assembly, Clamp-on Sensors 50mm – 700 mm. Non-Intrusive design requires no servicing with zero wearable parts – Accurate Bi-directional flow measurement and logging.

⚡ Electrical Calculator

🔌 Cable Size Reference

🌬 Unit Converter

🔋 Transformer VA & MCB Calculator

📊 Reference Guide

| Current (A) | Cable Size (mm²) |

|---|---|

| 6 | 1 |

| 6-12 | 1.5 |

| 12-25 | 2.5 |

| 25-32 | 4 |

| 32-40 | 6 |

| 40-64 | 10 |

| You must consider Ambient Temperature, Location and Thermal insulation in contact with cable. | |

Description

Fixed Ultrasonic Flow Meter Assembly: Clamp-on Sensors 50mm – 700mm

Fixed Non-invasive Flow Meter Assembly

Clamp-on Sensors 50mm – 700mm

Wall Mount Display: m3, Litres, Gallons etc

90-260V AC or 24V DC

Pulse, Alarm, 4-20mA Output, Modbus comms RTU or ASIC

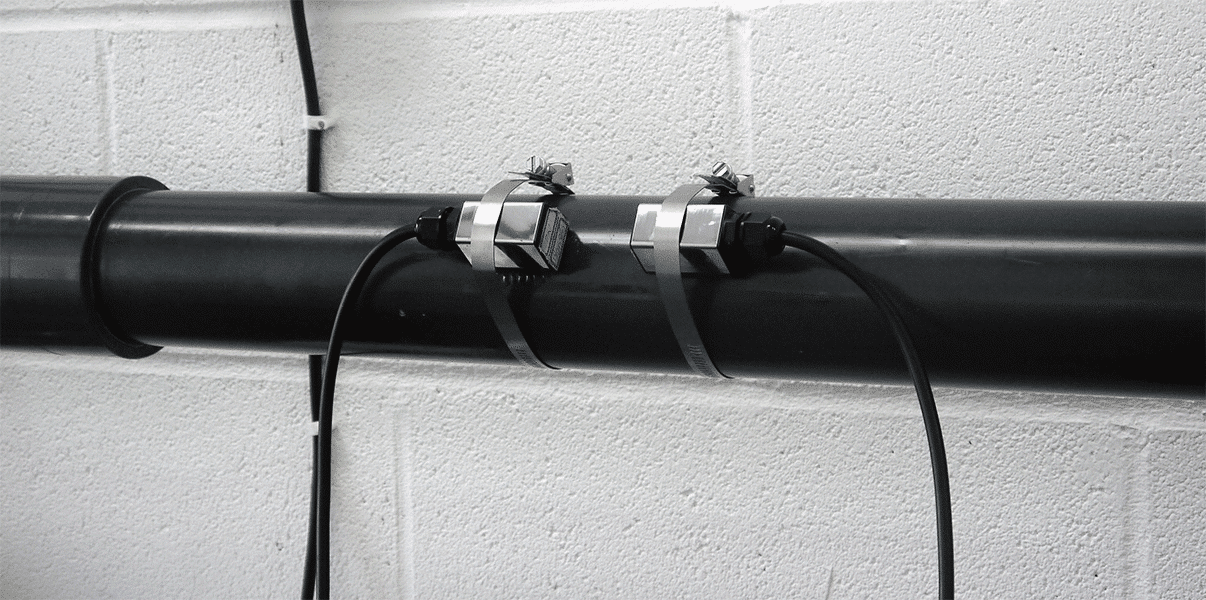

A non-intrusive Flow meter and volume flow display enable quick and easy installation of clamp-on flow sensors, without the need to make contact with water and cut into existing pipe work.

Specifications:

♦ Horizontal or vertical Installation

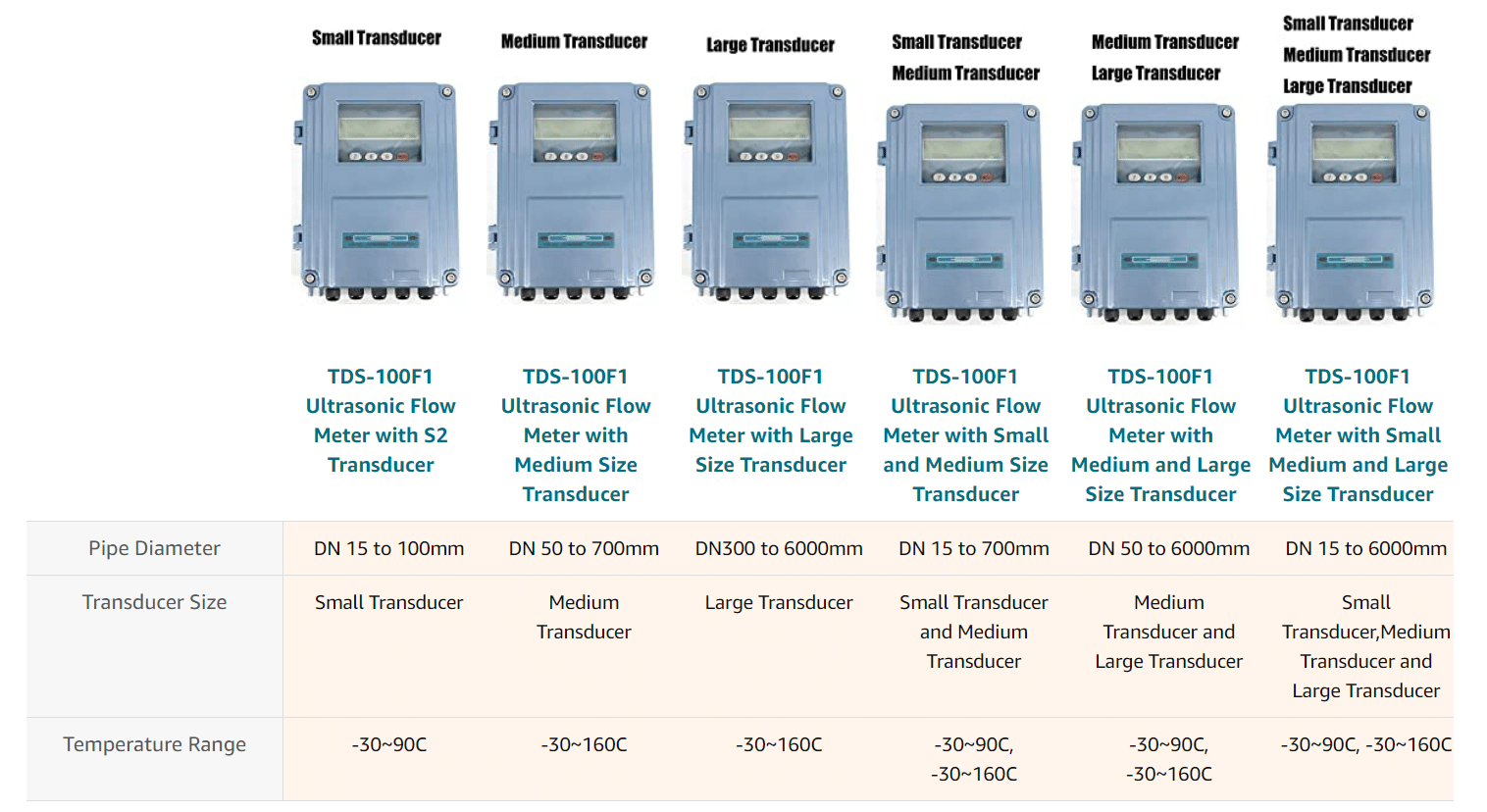

♦ Transducer Max Temp: -20C to +70C (160C option)

♦ Accuracy: <1% of reading above 0.6ft/sec / 0.2 m/sec

♦ Outputs: 1x 4-20mA , 1x Pulse Output , 1x Alarm Output, Modbus (All configurable

♦ Ingress Protection: Display= IP65, Transducers= IP65 (IP68 on request)

These flow meters can be used on any pipe size 50mm or above and on most pipe materials, including lined pipe. They are non-invasive and therefore not prone to the levels of deterioration seen with traditional intrusive flow meters, requiring little or no servicing.

| The specifications for the fixed ultrasonic flowmeter | |

| Measuring Principle | Ultrasonic wave transmission time difference principle, dual CPU working in parallel, 4-byte floating-point operations |

| Accuracy | Better than ± 1.0 % |

| Repeatability | 0.2% |

| Velocity | 0.03-± 32 m/s |

| Measurement Period | 0.5S |

| Display | A backlit LCD can display 2×20 letters, instantaneous flow, cumulative flow, velocity, time, calories, and other data signal outputs simultaneously. |

| Keypad | 4×4-key membrane keypad with tactile feedback |

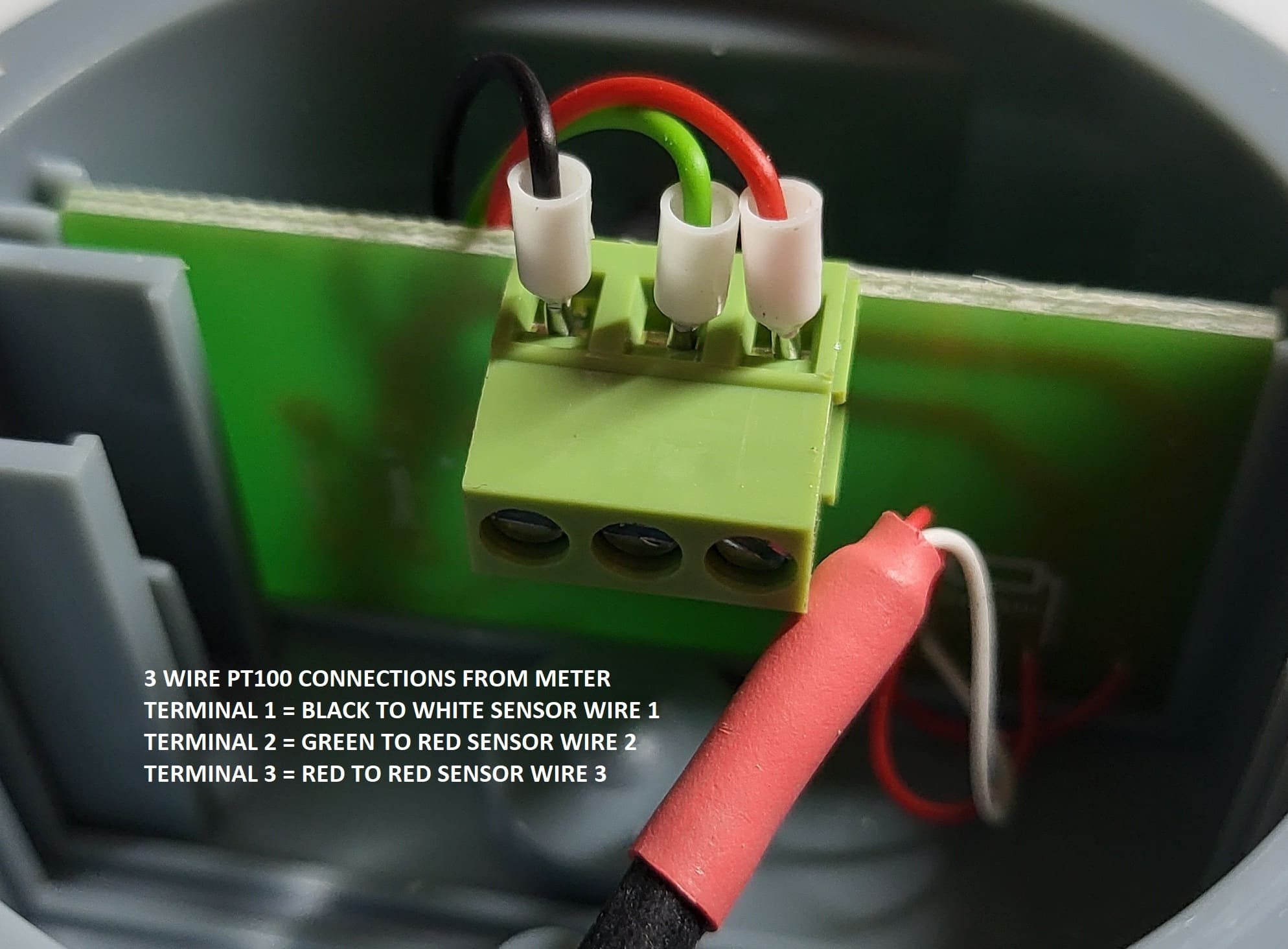

| Input | Can input two current signals(such as temperature, pressure, liquid level, etc.) in order to achieve heat measurements or a dual-purpose machine |

| Output | Electric current signal 4-20mA or 0-20mA, etc. RS 485 Impedance 0 – 1K, accuracy 0.1% |

| Isolated OCT output | For frequency output (0-9, 999Hz) |

| Internal Alarm (Buzzer) | User programmable |

| External Alarm Driver | The alarm signal can be transmitted to the Relay or OCT output terminals to drive an external alarm. |

| Data Interface | RS-232 serial port or MODBUS RTU/ASIC |

| Power | AC: 90V to 260V DC: 8~36VDC or AC7-30V |

| Power Consumption | < 2W |

| Work time | Continuous |

| Environment Temperature | -30-80 Degrees Celsius |

| Environment Humidity | 85% RH |

BFU-100-F Fixed Ultrasonic Flow Meter Assembly

Clamp-on Sensors 50mm – 700mm

Non-Intrusive design requires no servicing with zero wearable parts – Accurate Bi-directional flow measurement and logging.

Specifications:

♦ Horizontal or vertical Installation

♦ Transducer Max Temp: -20C to +70C (160C option)

♦ Accuracy: <1% of reading above 0.6ft/sec / 0.2 m/sec

♦ Outputs: 1x 4-20mA , 1x Pulse Output , 1x Alarm Output, Modbus (All configurable)

♦ Ingress Protection: Display= IP65, Transducers= IP65 (IP68 on request)

♦ Can be moved around the site as location specs are stored in memory

Applications

• Water / Wastewater / Effluent

• Hot Water / Chilled Water / Mixture of Water and Glycol

• Petroleum Products

• Oil / Crude Oil / Fuel Oil / Diesel/ BioDiesel / Lubricant

• Oil /Hydraulic Oil (non-aerated)

• Chemicals and Solvents

• Water management in buildings, Civil structures, District Heating/wastewater treatment plants, irrigation systems, and more

• Flow monitoring and flow control in Desalination plants, steel-making plants, power plants, and machining plants

• Liquid process control in chemical plants and industrial automation applications

• Retrofit capability, to upgrade or augment existing systems using this non-intrusive technology

• Automated batching

• Efficiency monitoring and improvement of heating/cooling systems, including solar/geothermal systems

• Hygienic Beverage, food, and pharmaceutical processing application

UartAssist – UartAssist serial debugging assistant V5.0.3 Software to check the Modbus communications from the heat meter.

BFU_RF Quick Start Guide

BFU

BFU_MANUAL

BFU_MODBUS INFO USER MANUAL

Additional information

| Amps |

4A, 6A, 8A |

|---|

Related products

-

Current Bar/Power Bar EB

LoRa Wireless RS485 transmitter and receiver with LCD screen – 2 Units

£260.00Original price was: £260.00.£160.00Current price is: £160.00. Add to basket -

LoRaWAN Devices

LoRa Wireless RS485 transmitter and receiver – 2 Units

£210.00Original price was: £210.00.£180.00Current price is: £180.00. Select options This product has multiple variants. The options may be chosen on the product page